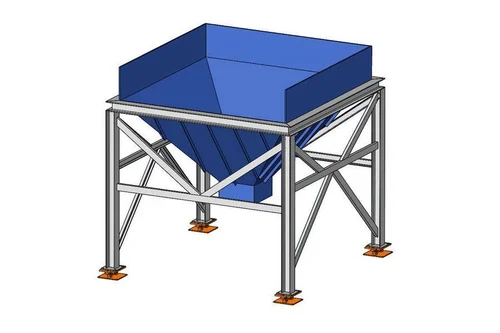

Hopper & Vessel Weighing Systems

Hopper & Vessel Weighing Systems deliver high-accuracy measurement for batching, dosing, and blending applications. Integrated with intelligent controllers, these systems support automated production processes, enhancing efficiency and consistency.

Hopper & Vessel Weighing Systems are designed for precise batching, dosing, and blending applications. They ensure process accuracy by continuously monitoring material weight during filling and discharge. Integrated with intelligent controllers, these systems improve production efficiency and product consistency.

- Food & beverage industry for mixing and portioning

- Chemical and paint industries for blending and dosing

- Pharma and biotech plants for precise recipe formulation

- Agriculture for feed mixing and fertilizer blending

- RetryClaude can make mistakes. Please double-check responses.

- High-accuracy load cells suitable for low to medium-capacity vessels

- Real-time weight monitoring for automated batching and recipe control

- Configurable alarms and outputs for overfill/underfill protection

- Compact mounting design with vibration isolation for stable readings

- Integration with printers, HMIs, and ERP systems for data recording

| Specification Name | Value |

|---|---|

| Models Available | WT-HWS-500, WT-HWS-1T, WT-HWS-5T, WT-HWS-10T |

| Capacity Range | 500 kg to 10 Ton |

| Load Cell Types | Shear Beam, Bending Beam, S-Type, Compression Load Cell |

| Accuracy | ±0.01% to ±0.02% |

| Output Options | 4-20mA, RS-485, USB, Modbus RTU, RS-232, Profibus, Modbus TCP/IP, Ethernet |

| Construction Materials | SS304/SS316, MS/SS304, Alloy/SS, SS316 |